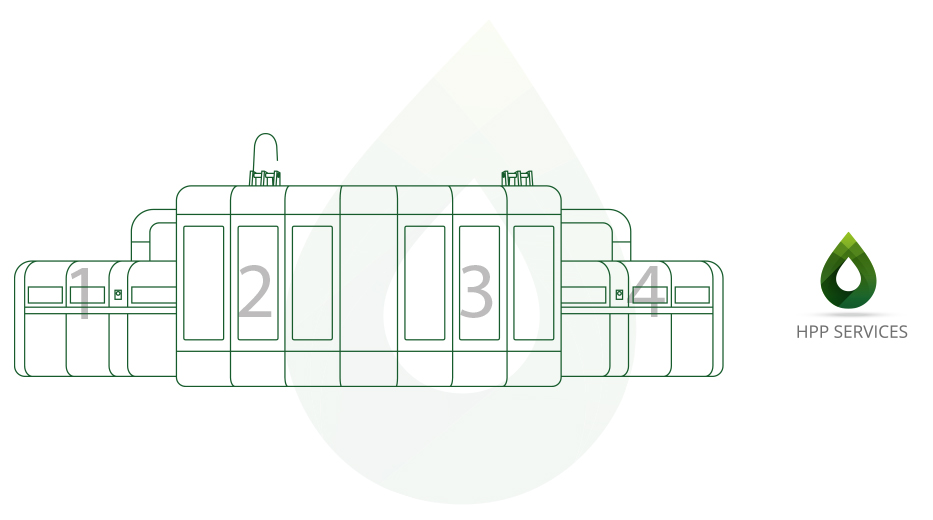

Science behind HPP? (High Pressure Processing)

High Pressure Processing offers both ecological and economic benefits. It needs only water and electricity for the high-pressure pumps. Germs and bacteria are completely neutralised without the use of chemicals. A step-by-step representation of the process is given below.

- The packaged food products are mostly cooled and put in special baskets. The process is suitable for vacuum packaging, skin packaging, modified atmosphere packaging, plastic bottles, pouches, … HPP requires flexible and semi-gastight packages.

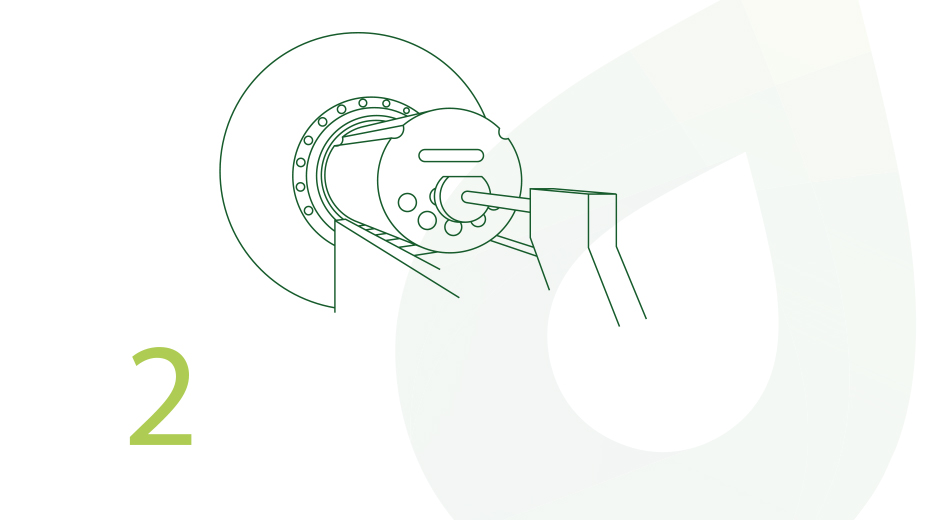

2. The baskets are transferred into the high-pressure vessel, which moves inwards and is sealed. The cold pasteurisation process can now start.

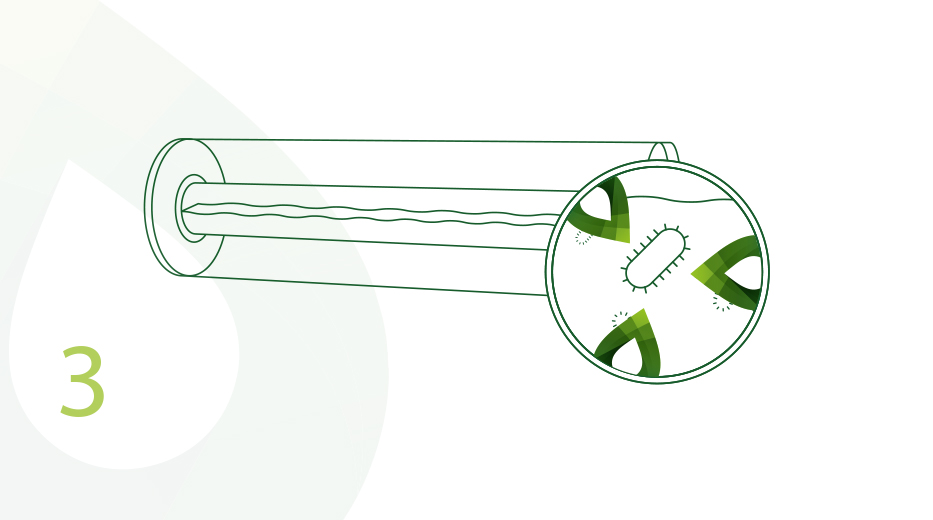

3. The steel vessel is filled with water. Then the electric high-pressure pumps increase the pressure in the vessel to a maximum of 6000 bar, killing germs and micro-organisms. Since the pressure is applied evenly from all sides, the product remains intact, without alterations of either structure or shape.

4. Once the pressure has been reduced, the water is drained off. The high-pressure vessel is opened and unloaded.

The result: food that remains fresh up to ten times longer, without texture, appearance or taste being affected in any way. Nutrients and vitamins are fully preserved and the product is ready to be transported and sold!

Please get in touch with us

Ask for more information or a free test run.