Benefits of HPP in terms of food safety

Improved food safety thanks to HPP (High Pressure Processing)

Statistics show that food safety is an extremely serious issue: every year, no less than 350,000 to 750,000 people are affected by food-borne infections and/or food poisoning. The YOPI population (Young, Old, Pregnant and Immunodeficient) is particularly vulnerable in this respect, which is why an additional process, such as HPP, is particularly important for this group.

HPP (High Pressure Processing) to eliminate secondary contamination

Pasteurisation subjects foods, both packaged and non-packaged, to heat treatment. However, with non-packaged foods, there is a risk of secondary contamination following production and during further processing. Because it is a post-packaging treatment, HPP totally eliminates this risk. HPP consequently not only extends the food’s shelf life by killing the microorganisms that spoil food, it also optimises food safety by eliminating the pathogenic microorganisms.

Economic impact

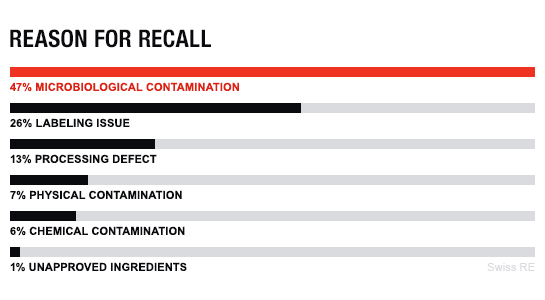

Food safety is not just an issue for the general population: it can also have an impact on the reputation and economic interests of the food producer. In Belgium, for example, there were more than 160 food-safety-related recalls in 2018. More than 38% were caused by the presence of pathogenic microorganisms in foods. All the more reason, therefore, to use HPP.

But remember: HPP treatment requires specific packaging methods.

Would you like to find out more? Read further on our page about advantages of HPP.

Do you need more information or are you interested in a free test run? Please contact us.

There are no comments